Food dust-free unpacking machine

product description

Our company's unpacking machine is used for unpacking and unloading bags of powdery and granular materials. Automatic unpacking and unloading of dry powdery materials in the fields of chemical industry, petroleum, building materials, metallurgy, electric power, food, medicine, grain, environmental protection, etc., such as protein powder, cassava, starch, monosodium glutamate, baking soda, milk powder, oatmeal, etc. It can carry out automatic bagging and unloading operations. It automatically feeds bags through a belt conveyor, automatically breaks bags with a cutting knife device, and automatically separates and unloads bags through vibrating screens. The materials fall into the storage hopper by gravity to complete the bagging and unloading work. . The dust generated during the operation is filtered out by the carried dust removal device, allowing workers to work in a clean environment.

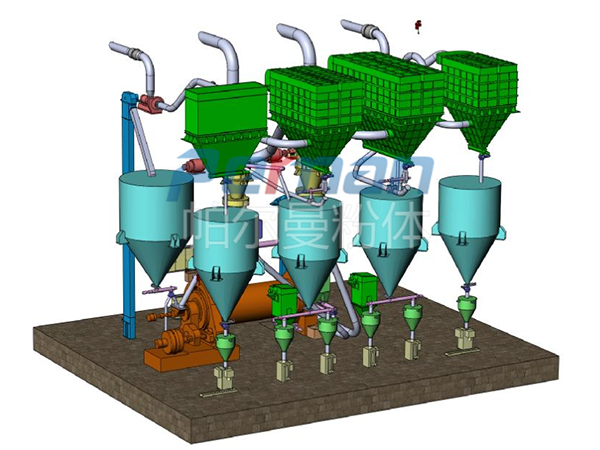

The unpacking machine is mainly composed of two parts: an inclined belt conveyor for feeding and a main machine. Among them, the feeding belt conveyor can be customized according to the requirements of the working site, and independently completes the transportation of bagged logistics, and finally allows the bagged materials to enter the inlet of the host machine. The main machine is composed of the main box, bag breaking device, screening device, material output device, waste bag output device and dust removal device.

Bag breaking device: The main working part of the bag breaking device is the cutting knife. The bagged powder materials are conveyed by the belt conveyor to the 45-degree sliding plate and then slide down the sliding plate by gravity. During the sliding process, five rapidly rotating cutting knives cut the packaging bag in multiple ways, allowing the material to be quickly separated from the waste bag. After separation, the cut waste bags and materials slide into the drum screen for screening. The entrance of the bag breaking device, that is, the entrance of the material, is equipped with a PVC curtain to prevent the material from splashing out of the box.

Screening device: In the screening device, the wall surface of the drum screen is covered with sieve holes, and 6 movable inclined plates are fixed on the surface of the sieve plate. This inclined plate acts as an internal spiral. The waste bags and materials enter the trommel screen, and the trommel screen rotates at a low speed, accelerating the materials to fall into the cone through the screen holes. The waste bags are spirally transported from the trommel screen to the drum outlet, and fall into the waste bag conveyor.

Material output device: The material in the cone hopper enters the screw conveyor in the material output device. The conveyor rotates the screw shaft to transport the material out of the machine and into the next process.

Waste bag output device: The waste bags coming out of the drum are transported to the long cylindrical bag outside the fully automatic unpacking machine for collection and processing under the action of the shaftless spiral in the waste bag output device. After the long cylindrical bag is filled, it is Manual replacement is performed manually.

Dust removal device: The dust removal device of the fully automatic unpacking machine is an integrated pulse dust collector, which is arranged above the automatic unpacking machine. It is small in size and has high dust removal efficiency; a quick-opening access door is set above to facilitate maintenance and bag replacement; a large-flow pulse injection valve , clean and fast, ensuring dust removal efficiency and extending the service life of the bag.

There are observation holes on both sides of the box of the fully automatic unpacking machine to facilitate observation of the internal operation of the machine. There are access doors on both sides of the observation hole and above the waste bag conveyor to facilitate machine installation and troubleshooting.

This machine is easy to operate, sensitive and reliable in shutdown.

Technical features:

1. The material bag breaking process and material separation process are fully enclosed, and each process is equipped with a dust collection device. There is no dust leakage and low noise, which improves the working environment of workers.

2. Only one or two people are required to place the packaging bags on the belt conveyor at the site, which reduces the intensity of the workers' work.

3. The equipment is simple to operate, reliable, has a low failure rate, and reduces maintenance workload.

4. The equipment is specially designed to perfectly separate the broken packaging bags from the materials. They will not be mixed into the materials or hung in the separation device.

5. The equipment automatically counts, and the bag loading amount can be set arbitrarily. When the set bag loading amount is reached, the equipment automatically stops.

6. Automatic alarm and emergency stop when equipment fails to protect equipment and avoid misoperation by personnel.

7. After bag breaking, unloading and separation, it can be used with other conveying equipment to complete functions such as powder conveying and storage.

8. Packaging bags of different sizes can be processed without adjusting the equipment.

Technical Parameters:

Main components of the equipment: 1. Feeding device 2. Bag breaking device 3. Separation device 4. Dust removal device 5. Conveying device 6. Automatic control

Bag breaking capacity: 100-800 bags/hour

Machine power: 10-17kw

Note: The configuration, output, material, power, etc. of the entire set of equipment of the automatic unpacking machine will change due to changes in material properties, usage occasions, discharging methods, etc.